- Jeffchen2121@gmail.com

- +86-18688742252

- Language

Gift packaging box common process-embossing and concave-convex process

Mon Jan 24 17:49:29 CST 2022

Gift packaging box common process-embossing and concave-convex process

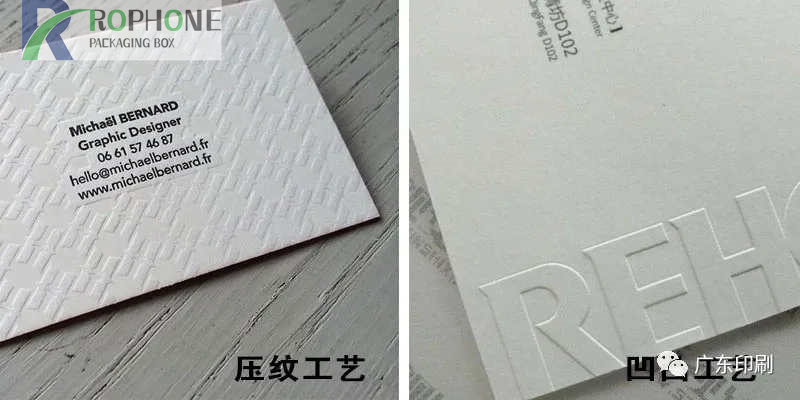

1. The common process of gift packaging box-embossing

Embossing is a commonly used process in the gift packaging box printing process. It uses a concave-convex mold and a pressure printing process determined by a press, so that the surface of the printed gift packaging box is produced according to the corresponding pattern of the mold. It is a printing process for surface processing. So what are the benefits of embossing in the gift packaging box?

Embossing can make the plane pattern three-dimensional and increase the infectiousness of the gift packaging box. It can also be used to emboss the paper as a whole, so that the entire gift packaging box can produce a completely different texture and three-dimensional effect from other papers. We have a gift packaging box. Customers need to customize and find a special paper pattern for their new product, mainly because the texture of the special paper is very close to their product, but the output and cost of the special paper they need exceeds them. We recommend that they use coated paper with full embossing. The embossed pattern can be provided by them, which solves their doubts in terms of cost and usage.

In fact, the embossing process is not only used in the process of making the gift packaging box, but also other handicrafts will also use a large number of embossing processes. In the gift packaging box printing, the embossing process can immediately improve the quality of the product.

If you also like the embossing process, you can contact us Rophone Packaging. Rophone Packaging, a manufacturer specializing in gift packaging box.

The difference between the embossing process and the concave-convex process of the gift packaging box

Nowadays, gift packaging box is an indispensable existence in real life, gift packaging box has been enjoyed by everyone, and the packaging industry is also developing at a high speed, known as the "sunrise" industry. With the continuous introduction of new products, the demand for gift packaging boxes will continue to increase, and consumers' aesthetics will become increasingly strict. Customers also put forward higher requirements for the production quality and craftsmanship of gift packaging boxes.

For gift packaging box companies to successfully complete each batch of products, they need a series of efficient management to cooperate with each other. The gift packaging box production process is an important part of management that is worth noting. The packaging production process includes design, plate making, printing, surface decoration, die cutting, box gluing and other process treatments, and the entire product production is completed through these processes. In these processes, the embossing process and the embossing process in the surface decoration are not clear to many customers, so what is the difference between the embossing process and the embossing process of the cover of the gift packaging box?

1. Embossing process of gift packaging box

The embossing process is a common gift packaging box surface decoration process. It uses a concave-convex texture mold to deform the pressure-bearing packaging material under a certain pressure and temperature, forming an obvious relief three-dimensional effect, and enhancing the gift The artistic appeal of the cover of the packaging box. The embossing process is generally full-page embossing, and the depth of the texture is related to the thickness of the packaging material. In the market, general-purpose texture molds are generally used. If the quantity is large, special texture die-cutting can be customized.

2. Concave-convex process of gift packaging box

The concave-convex process is the most commonly used process to improve the tactile effect of the gift packaging box. It is to engrave the text or pictures of the design draft on the metal plate, and the packaging material is deformed by the pressure of the machine. The concave-convex process The height and area of the gift box can bring a different three-dimensional effect to a special part of the gift box packaging. Generally, the embossing process is only used for text, pictures, etc., not the entire page. The height of the embossment is related to the thickness of the packaging material.